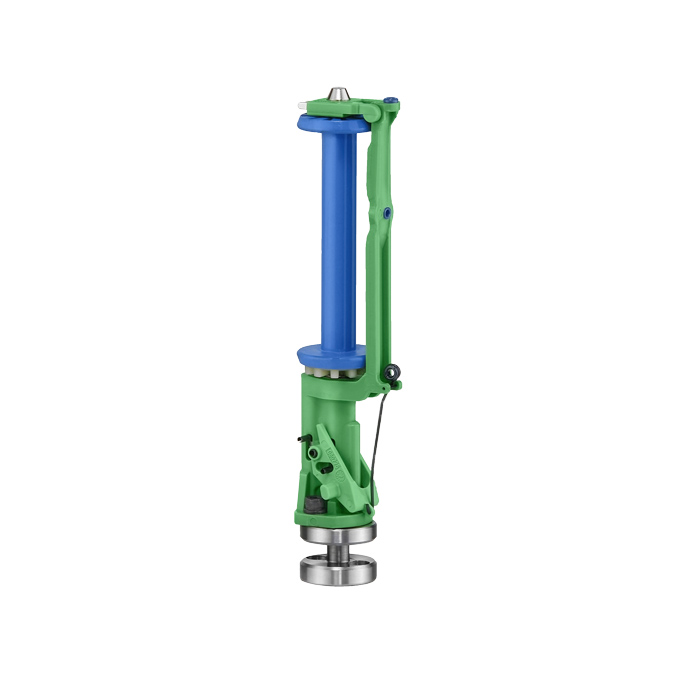

The carrier is an essential component used in various industries for specific applications. It plays a crucial role in supporting and guiding the bobbin during the winding process.

Designed to accommodate specific bobbin sizes, the carrier ensures a secure and stable placement of the bobbin. With dimensions of 43mm×113mm, it is compatible with a range of bobbins used in different manufacturing processes.

The carrier is also equipped with a horn gear, which measures 80mm in size. The horn gear works in conjunction with other components to drive the bobbin and facilitate the winding operation. Its precise size ensures smooth and efficient rotation, enabling the winding process to be carried out accurately and effectively.

The selection of the carrier is important as it directly affects the performance and quality of the winding process. Different carrier types may be available, each designed to meet specific requirements and applications. It is essential to choose the appropriate carrier type based on factors such as the thread material, bobbin size, and desired winding outcome.